Phased Array Corrosion Mapping

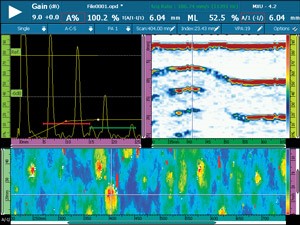

PAUT Corrosion analysis is proving to be a very cost effective and accurate alternative to the previous “shadow shot” performed with Radiography, then followed by D-meter thickness readings. PAUT allows full 360° coverage of any pipe greater than 2” NPS up to a flat surface. PAUT allows the client the capability of accurate and repeatable results for any project for any size pipe or tank. PAUT corrosion analysis can be performed either manually or semi-automatically, dependent on the material and geometry of the part being inspected. Accurate sizing, depth and extent of corrosion can be saved and given to client as part of the PUAT corrosion report.

PAUT Corrosion analysis is proving to be a very cost effective and accurate alternative to the previous “shadow shot” performed with Radiography, then followed by D-meter thickness readings. PAUT allows full 360° coverage of any pipe greater than 2” NPS up to a flat surface. PAUT allows the client the capability of accurate and repeatable results for any project for any size pipe or tank. PAUT corrosion analysis can be performed either manually or semi-automatically, dependent on the material and geometry of the part being inspected. Accurate sizing, depth and extent of corrosion can be saved and given to client as part of the PUAT corrosion report.

UT Limitations

As with any NDT method, there are limitations that arise. Many can be corrected and other cannot:

- Cleanliness of material to be examined is of the utmost importance. Any material requiring UT inspection, either conventional or PAUT, must be free and clear of any rust, scale, debris, surface corrosion, coating or thick paint.

Discontinuities running parallel to the incident angle may go unnoticed and are usually undetectable with UT - UT is not the best method to detect porosity

- Geometry of the part and accessibility, are deciding factors on the extent of capable UT

- Technician training is more advanced that other NDT methods

- Evaluation of weld type indications are subject to technician interpretation and may not be as accurate as RT inspection. UT inspection is based off a sound reflection and not a physical image as seen on a radiograph. Therefore, the use of the term “reflector” is often used by the UT technician when reporting a weld discontinuity notice during the examination.

- For PAUT and conventional UT weld inspection, material thickness less then 6mm will result in inconclusive results as the pulse responses shown on the instrument are very difficult to resolve with any form of accuracy.

- High temperature piping greater than 93C require specialized transducers and couplant for any longitudinal inspection.

- Higher temperature weld inspection cannot be performed with the current capabilities of Cave Inspection